The Pierrel production

We are specialized in aseptic production of dental anaesthetics, in compliance with high international quality standards and with the adoption of cutting-edge technologies.

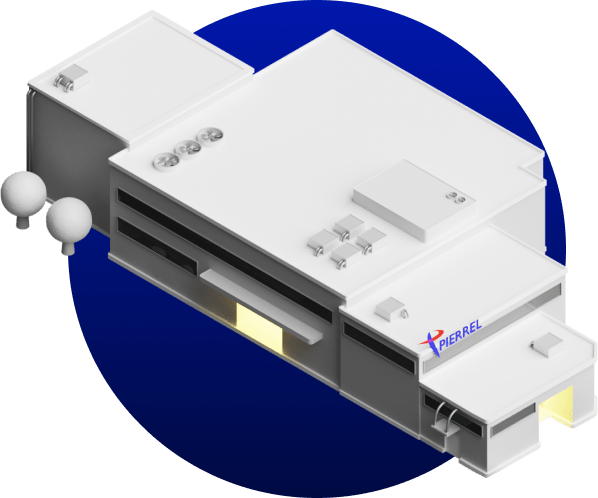

The production site and the headquarters are in Capua, in the south of Italy a few kilometers from Naples. The premises is spread over a surface of 40,000 square meters, of which 11,000 square meters covered: 6000 square meters for the production departments and the remaining areas used as a warehouse (with the possibility of storing in rooms at different temperatures, at 2-8 sections C, 15 and 25 seasons C), chemical and microbiological laboratories as well as offices.

We are authorized by EMA (European Medicines Agency) and FDA (Food & Drug Administration) to produce aseptic dental anesthetics.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store user consent for cookies in the "Analytics" category. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by the GDPR cookie consent to record the user's consent for cookies in the "Functional" category. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by the GDPR Cookie Consent plugin. Cookies are used to store user consent for cookies in the "Necessary" category. |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store user consent for cookies in the "Others" category. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store user consent for cookies in the "Performance" category. |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| JSESSIONID | session | The JSESSIONID cookie is used by New Relic to store a session identifier so that New Relic can monitor session counts for an application. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plug-in and is used to store whether or not the user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 2 years | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_19T11805C2 | 2 years | This cookie is installed by Google Analytics. |

| _ga_devsite | 2 years | This cookie is installed by Google Analytics. |

| Cookie | Duration | Description |

|---|---|---|

| li_gc | 2 years | No description |

| wp-wpml_current_language | session | No description available. |